|

Scraper Conveyor Chains

Scraper Conveyor Chains Specification

- Bore Size

- As per specification

- Usage & Applications

- Used in material handling, bulk conveying, and scraper conveyors

- Product Type

- Scraper Conveyor Chains

- Material

- Steel

- Surface Treatment

- as per selection

- Teeth Number

- As per requirement

- Front Gear

- Available as per design

- Rear Gear

- Available as per design

- Size

- Customized sizes available

- Breaking Load

- High tensile strength for heavy-duty applications

- Pin Diameter

- Precision manufactured

- Assembly

- Fully assembled or knock-down as specified

- Link Plate Thickness

- Engineered to specification

- Operating Temperature

- Suitable for a wide range (as required)

- Corrosion Resistance

- Optional coatings upon request

- Chain Type

- Single, double, or multiple strands

- Lubrication

- Self-lubricating options or manual lubrication

- Chain Pitch

- Standard and custom pitches available

- Hardness

- Surface hardened for durability

Scraper Conveyor Chains Trade Information

- Minimum Order Quantity

- 100 meters Meters

- Payment Terms

- Letter of Credit (L/C), Cash on Delivery (COD), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Delivery Time

- 5 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard packaging

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Western Europe, Asia

- Main Domestic Market

- All India

About Scraper Conveyor Chains

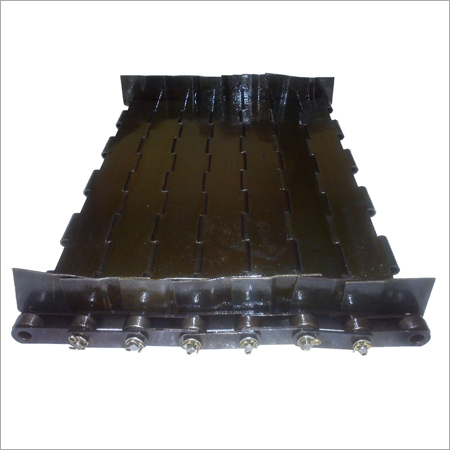

Scraper Conveyor Chains

It is a type of flight conveyor, that consists of a trough in which a continuous driven chain with flights is running. The flights are scraping the material over the bottom of the casing. It incorporates the conveyor chain, the chain connectors, the drive wheels, guide wheels, and the scrapers with their attachments. The design is ideal for slower transportation speeds over short distances, on moderate inclines, or even under water.

Engineered Durability for Heavy-Duty Conveying

Designed for bulk material handling, our scraper conveyor chains feature high tensile strength, advanced surface hardening, and customizable options for demanding environments. Whether you require standard or unique specifications, we provide solutions that enable reliable operation across a wide temperature spectrum and resist wear in challenging conditions.

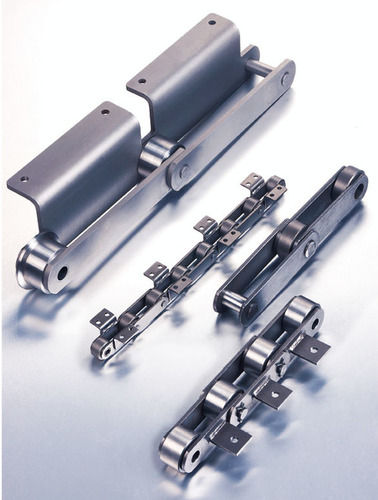

Precise Manufacturing for Versatile Applications

Every chain is manufactured to exacting standards, ensuring precision in pin diameter, link plate thickness, and gear integration. Our chains accommodate single, double, or multiple strands, making them suitable for a variety of conveyor and material transport systems in industries such as manufacturing, mining, or agriculture.

FAQs of Scraper Conveyor Chains:

Q: How are scraper conveyor chains customized to fit specific applications?

A: We customize scraper conveyor chains by adjusting pitch, number of strands, link plate thickness, pin diameter, bore size, and surface treatments. This ensures the chain aligns with your specific load requirements, operational environment, and conveying needs.Q: What materials and surface treatments are available for these chains?

A: Our chains are primarily constructed from high-grade steel. We offer a variety of surface treatmentsincluding hardening for wear resistance and optional corrosion-resistant coatings for harsh environmentsbased on your applications demands.Q: When should I choose a fully assembled versus knock-down chain assembly?

A: A fully assembled chain is ideal when immediate installation is needed, minimizing downtime. Knock-down assemblies are preferred if you require on-site assembly, easier transport, or wish to stock replacement parts more efficiently.Q: Where can these chains be used effectively?

A: Scraper conveyor chains are widely used in bulk material handling, manufacturing, mining, agriculture, and any systems involving scraper conveyors. Their robust design makes them suitable for both standard and challenging operational settings.Q: What is the process for ensuring precision in manufacturing?

A: We adhere to rigorous manufacturing standards, using precision engineering for pin diameters and link plates, and conduct thorough quality checks throughout the production cycle to guarantee a reliable, high-performance chain.Q: How does self-lubrication benefit conveyor chain operation?

A: Self-lubricating options reduce maintenance needs, prevent premature wear, and extend service life, making them ideal for applications where regular manual lubrication is challenging or inaccessible.Q: What are the key advantages of your scraper conveyor chains for heavy-duty applications?

A: Key advantages include high breaking load for heavy-duty use, customizable dimensions, excellent surface durability, resistance to corrosion, and flexibility in assembly as well as gear compatibility. All these enhance reliability and operational longevity.

Price 2000 INR/ Meter

- Minimum Order Quantity

- 100 meters Meters

- Delivery Time

- 5 Week

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Central America, Western Europe, Asia

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chain Sprockets Category

Scraper Conveyor Chains 2

Price 1500 INR / Meter

Minimum Order Quantity : 100 meters Meters

Material : Steel

Surface Treatment : as per selection

Solid Pin Conveyor Chains

Price 1500 INR / Meter

Minimum Order Quantity : 100 meters Meters

Material : Steel

Surface Treatment : as per selection

Extended Pin One Sided Conveyor Chain

Price 1500 INR / Meter

Minimum Order Quantity : 100 meters Meters

Material : Steel

Surface Treatment : as per selection

|

CONKORD ENGINEERING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |